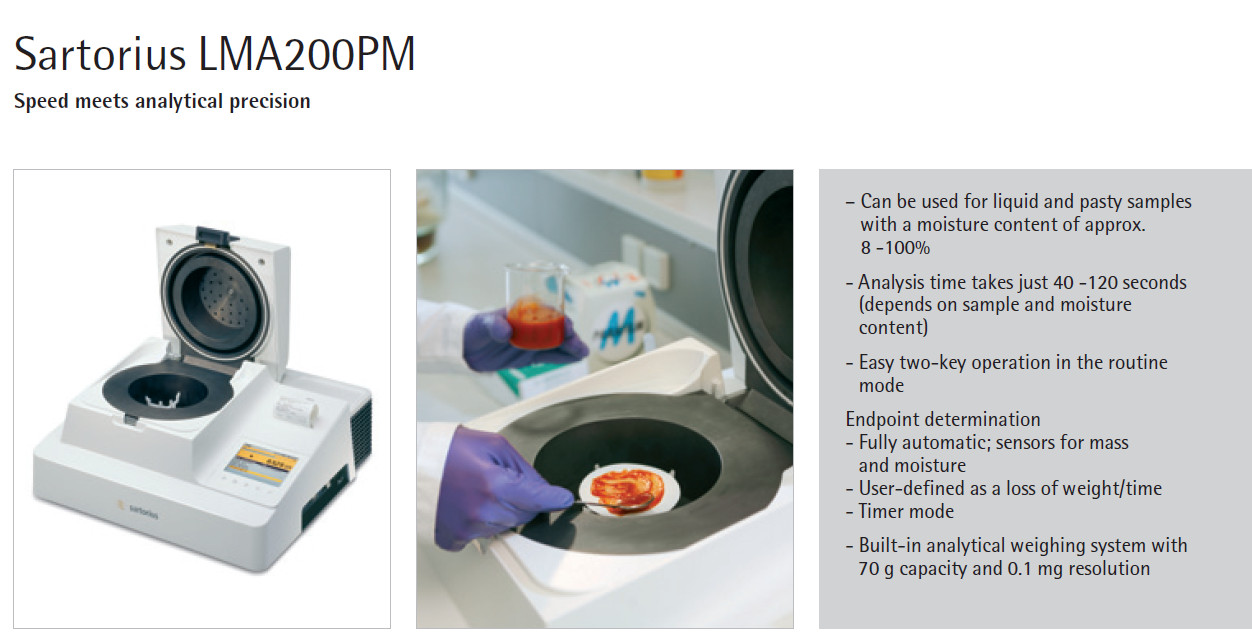

If the sample contains a high moisture

content, microwave drying is the fastest and

most effective thermogravimetric method

(loss-on-drying principle) for moisture

analysis. Developed for measuring moisture

content ranging from approx. 8% to 100%,

the LMA200PM performs moisture analysis

in a fraction of the time it takes for other

thermogravimetric methods. It delivers results

between approx. 40–120 seconds on average.

With a cylindrical design, a focused emission

of microwave energy is channeled vertically

through dual apertures at the bottom of the

chamber. This concentrates the microwave

energy specifically to the sample. During the

test, a carousel spins the sample, permitting

an even distribution of microwave energy.

This prevents hot and cold spots from occurring,

a familiar problem with conventional

microwave analyzers.

Built-in analytical weighing system

The moist and dry weight of the sample

required for calculating the loss of moisture

is measured by a built-in analytical weighing

system featuring 0.1 mg resolution. Thanks

to its monolithic design (the cell is robotically

etched from a single block), this system is

particularly suitable for use in a moisture

analyzer, because it considerably reduces zero

point drift during heat exposure compared

with classic weighing systems.

Intelligent endpoint determination

A moisture sensor integrated in the exhaust

system of the sample chamber monitors the

progress of drying. When the measurement

begins, the moisture of the air inside the sample

chamber continuously increases as water

evaporates from the sample. Once the sample

has dried and no longer releases water, the

air moisture content drops back to its original

level – a clear indication of the end point.

At the same time, the built-in weighing system

monitors the weight progression and

confirms when the sample reaches a constant

weight. This dual monitoring system ensures

optimal moisture analysis results.

High speed

Two factors play a major role for ultra-fast

measurements. First, the sample must absorb

microwave energy within the shortest time

possible and transform this into heat energy.

For this purpose, the LMA200PM has a

cylindrically shaped sample chamber that

optimally focuses the microwave radiation

on the sample. Second, the resulting water

vapor must be transported away from the

sample as fast as possible to obtain fast

analysis results. To accomplish this, a sample

is applied to a glass fiber pad that allows

water vapor to evaporate not only from top

of the pad and upward through the sample,

but also from the bottom of the pad. An

exhaust system draws water vapor out of the

sample chamber, thus preventing the effects

of condensation.

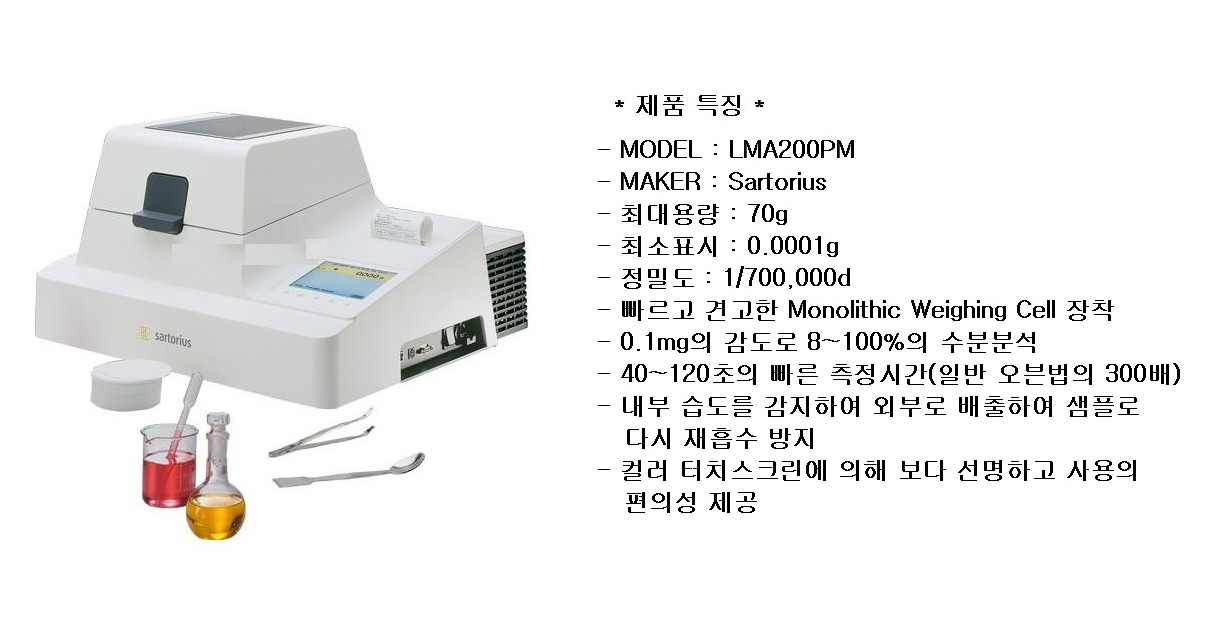

상품정보고시

| 제품명 |

미량수분계, LMA200PM |

| 판매가격 |

18,120,000원 |

| 브랜드 |

Sartorius |

| 원산지 |

독일 |

| 제조사 |

Sartorius |

반품교환 |

구입제품의 이상이 있을 경우

- 구입후 7일 이내에 동일제품으로 교환 가능하며 운송비는 판매자 부담입니다.

- 다른 제품으로 교환, 또는 이상이 없는 제품과 함께 교환을 원하실 경우 구매자께서 운송비를 부담합니다.

구입제품의 이상이 있을 경우 (색상,사이즈,다른상품교환)

- 구입후 7일이내 교환 가능하며 구매자께서 운송비를 부담합니다.

!! 주의사항

비닐포장 및 Tag의 폐기 또는 훼손 등으로 상품 가치가 멸실된 경우에는 제한.

반품시에 해당 사은품이 있을 경우 같이 보내주셔야 합니다. |

배송안내 |

결제후 3~7일 이내에 상품을 받아 보실 수 있습니다.

국내 최대의 물류사 KG로지스택배를 통하여 신속하고 안전하게 배송됩니다.

모든 제품은 착불 발송됩니다. 단 30만원 이상 구입시 택배무료배송입니다.

(제주도를 포함한 도서,산간지역은 항공료 또는 도선료가 추가됩니다.)

화물(용달),퀵 이용은 구매자께서 운송비를 부담합니다.

|

결제안내 |

결제방법은 신용카드, 국민/BC(ISP), 무통장입금, 적립금이 있습니다.

정상적이지 못한 결제로 인한 주문으로 판단될 때는 임의로 배송이 보류되거나,주문이 취소될 수 있습니다. |